The Role of Stack Flow Sensors in Industrial Air Quality Control

In the realm of industrial operations, maintaining high air quality standards is not just a regulatory requirement; it's a fundamental responsibility. Ensuring that the emissions from industrial processes meet stringent environmental guidelines is vital for the health of our planet and the well-being of communities. In this context, stack flow sensor play a pivotal role in industrial air quality control, offering precise and reliable measurement solutions.

Understanding Stack Flow Sensors

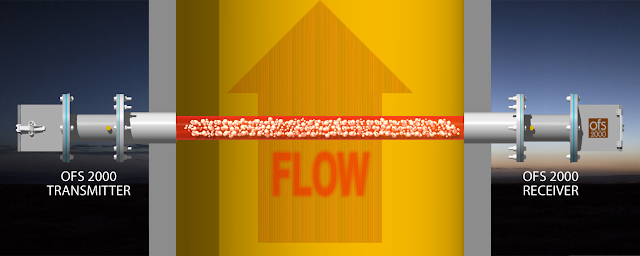

Stack flow sensors are sophisticated devices designed to measure the volumetric flow rate of gases being discharged from industrial stacks or chimneys. These sensors are critical in determining the quantity of pollutants released into the atmosphere, allowing industries to monitor and control their emissions effectively.

The Significance of Accurate Measurements

Stack flow sensors play a

pivotal role in ensuring compliance with environmental regulations. Regulatory

bodies set strict limits on emissions of various pollutants such as particulate

matter, sulfur dioxide, nitrogen oxides, and volatile organic compounds.

Industries are required to continuously monitor and report their emissions to

demonstrate compliance.

Accurate flow

measurements provided by stack flow sensors are the foundation of precise

emissions calculations. Without reliable data, industries risk falling out of

compliance, potentially leading to fines, legal issues, and damage to their

reputation. Moreover, monitoring emissions is not just about complying with

regulations but also about minimizing environmental impact and contributing to

sustainability efforts.

Flare Line Flow Sensors: A Complementary solution in some industrial processes, particularly in petrochemical facilities, flare stacks are used to burn off excess gases to prevent hazardous conditions. Flare line flow sensor serve a similar purpose to stack flow sensors but are tailored to the unique demands of flare stack monitoring. These sensors accurately measure the flow of gases in flare lines, helping operators optimize combustion efficiency and reduce emissions.

By combining

data from both stack flow sensors and flare line flow sensors, industries can

gain a comprehensive understanding of their emissions across various points in

their operations. This holistic approach enables better decision-making and the

implementation of strategies to reduce environmental impact effectively.

Conclusion

Stack flow sensors and

flare line flow sensors are indispensable tools in the realm of industrial air

quality control. These devices enable industries to accurately measure and

manage their emissions, ensuring compliance with environmental regulations and

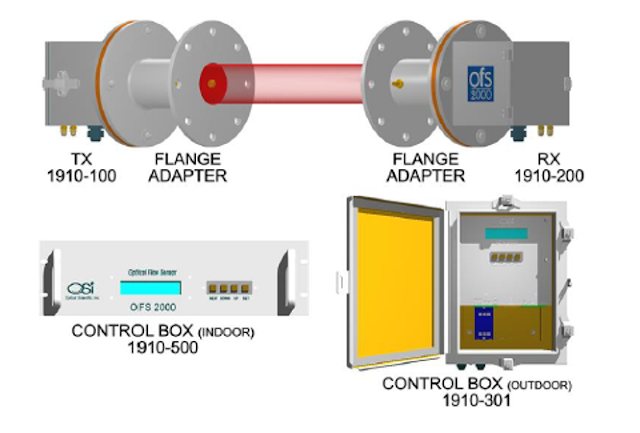

contributing to a cleaner, healthier planet. Companies like Optical Scientific

play a crucial role in advancing the technology and expertise needed to

safeguard our environment while maintaining efficient industrial processes.

As industries

increasingly recognize the importance of environmental responsibility,

companies like Optical Scientific have emerged as leaders in providing

cutting-edge solutions for air quality control. Optical Scientific specializes

in advanced stack flow sensors and flare

line flow sensors that meet the rigorous demands of industrial

applications.

Comments

Post a Comment