Flow Measurement Processes are Necessary for Enhanced Quality and Control

Measuring the flow of atmospheric turbulence, wind pressure, and precipitation should be quality-sensitive and control-oriented. A proper balance between the day-to-day atmospheric changes can’t be established if this doesn't happen. Through this, playing with efficiency and consistency doesn’t appear a tough nut to crack. Are you or your Gaithersburg friends confused about whether the process flow measurement techniques are helpful here? This blog explains their impact in real-time and how they are honest in following industry standards.

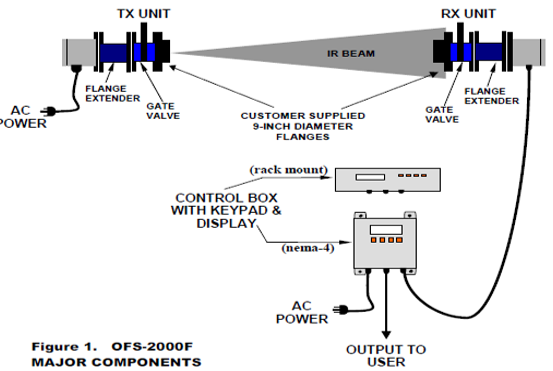

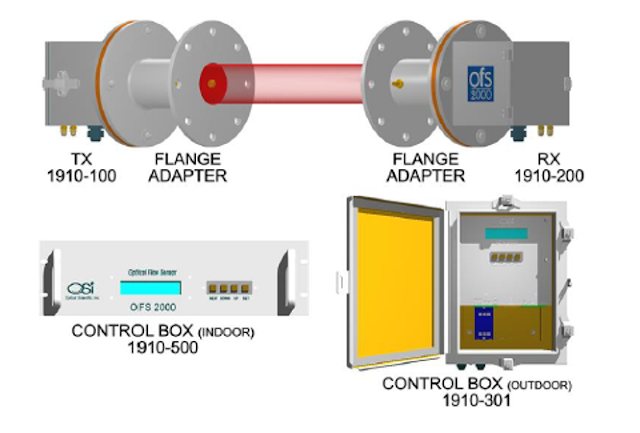

Industry-oriented and functionalGuiding the people working in the engineering team and pressure and wind control departments demands a strong focus on industry standards. To achieve this, a visual representation of the non-contact flow sensor workflow and the associated tasks adds magic in the form of subsets supporting OSI computing standards. After this, giving a tough fight to the business competitors appears more confident and joyful. What else is now left to grasp the functional strength of such workflows with which modeling and executing flow measurement processes are profit-oriented and adjust faster with technological advancements?

Sensitive to quality and control standards

From storing weather updates location-wise to governing a series of transformations in terms of resource quality, all of this is well-monitored with no hiccups. Moreover, the process flow measurement timelines followed greatly simplify the utilization of energy resources a system may access. Take pride in supervising and delivering real-time insights into weather fluctuations. Be systematic when it comes to monitoring, executing, and controlling the processes and setting the status of their tasks. Let a sense of ownership achieve the trust of stakeholders, technicians, and environmental compliance experts sooner than expected.

Conclusion

Flow measurement techniques are always process-oriented and sensitive

to catching gaps between quality inspection and control. They understand the

need to access weather updates and abate with them as the need arises. Improving

the quality efficiency at every step of the workflow becomes necessary to make

it less complex. It in the longer run assures that industry standards are

followed and regulated at different time intervals. Optical Scientific and the

team of exceptional wind pressure and precipitation measurement experts are

serious about following compliance standards at times achieving the highest

level of quality and control becomes unavoidable. They are well aware of

identifying and supplying outcomes that establish a proper balance between the

components like temperature, wind, and turbulence. To know more about the

research and development potential of a non-contact flow sensor,

automated weather monitoring, and additional weather stations installed and

configured at industrial and commercial sites nearby Maryland shopping malls or

riverside areas, visit the official website of Optical Scientific now. Get in

touch with the team organizing and managing the flow sense and measurement

processes.

Call us at 301-963-3630

For more info visit us: https://www.opticalscientific.com/

Comments

Post a Comment